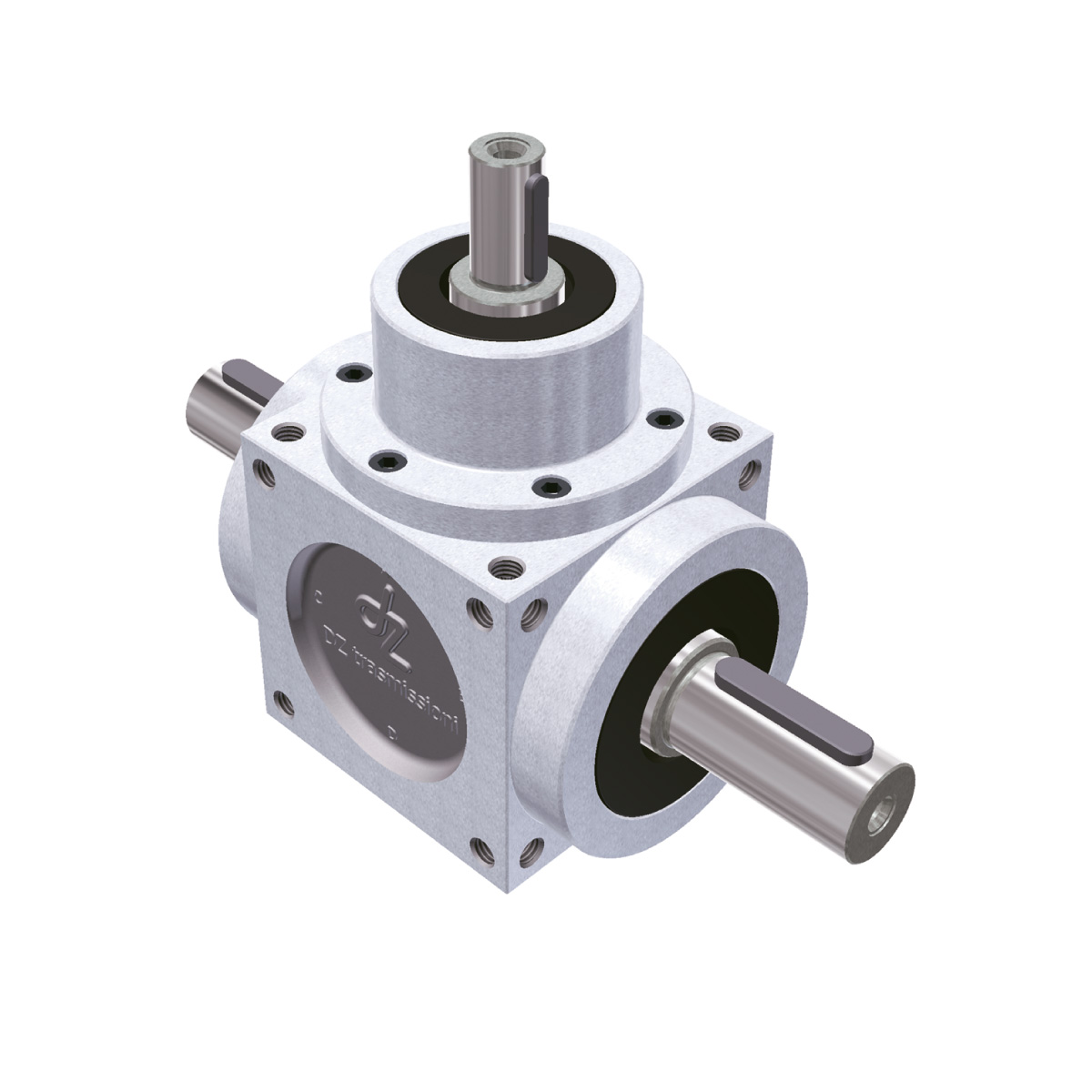

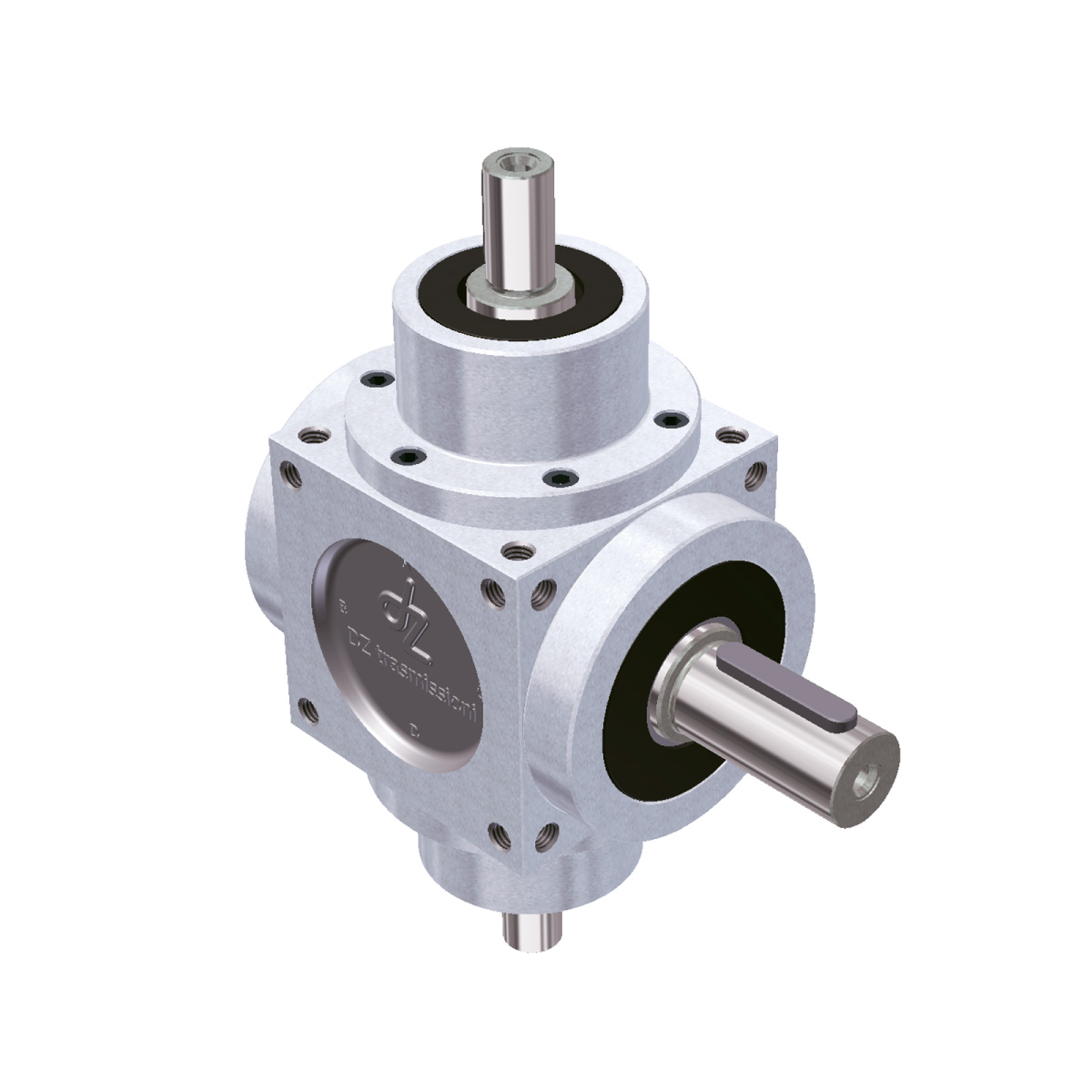

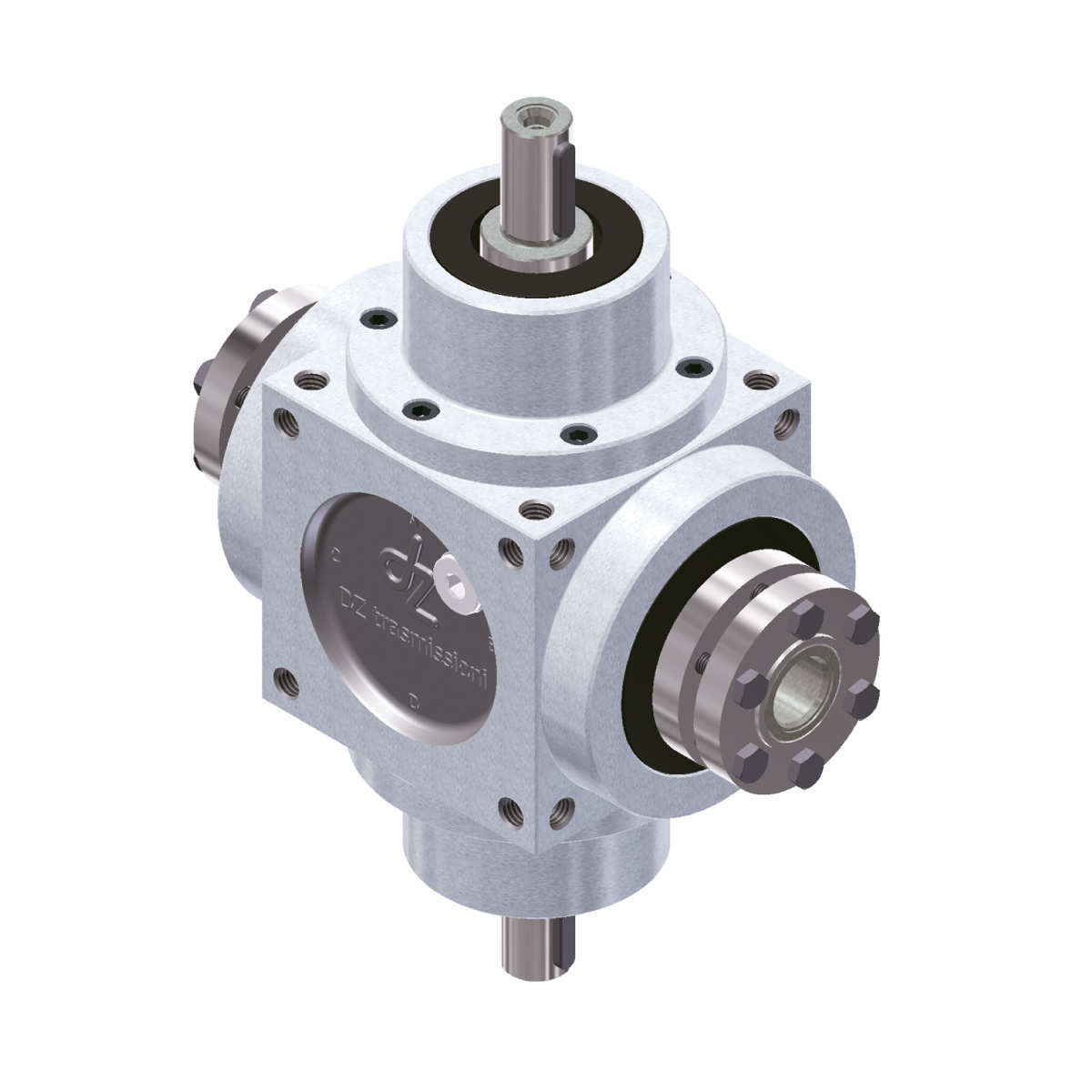

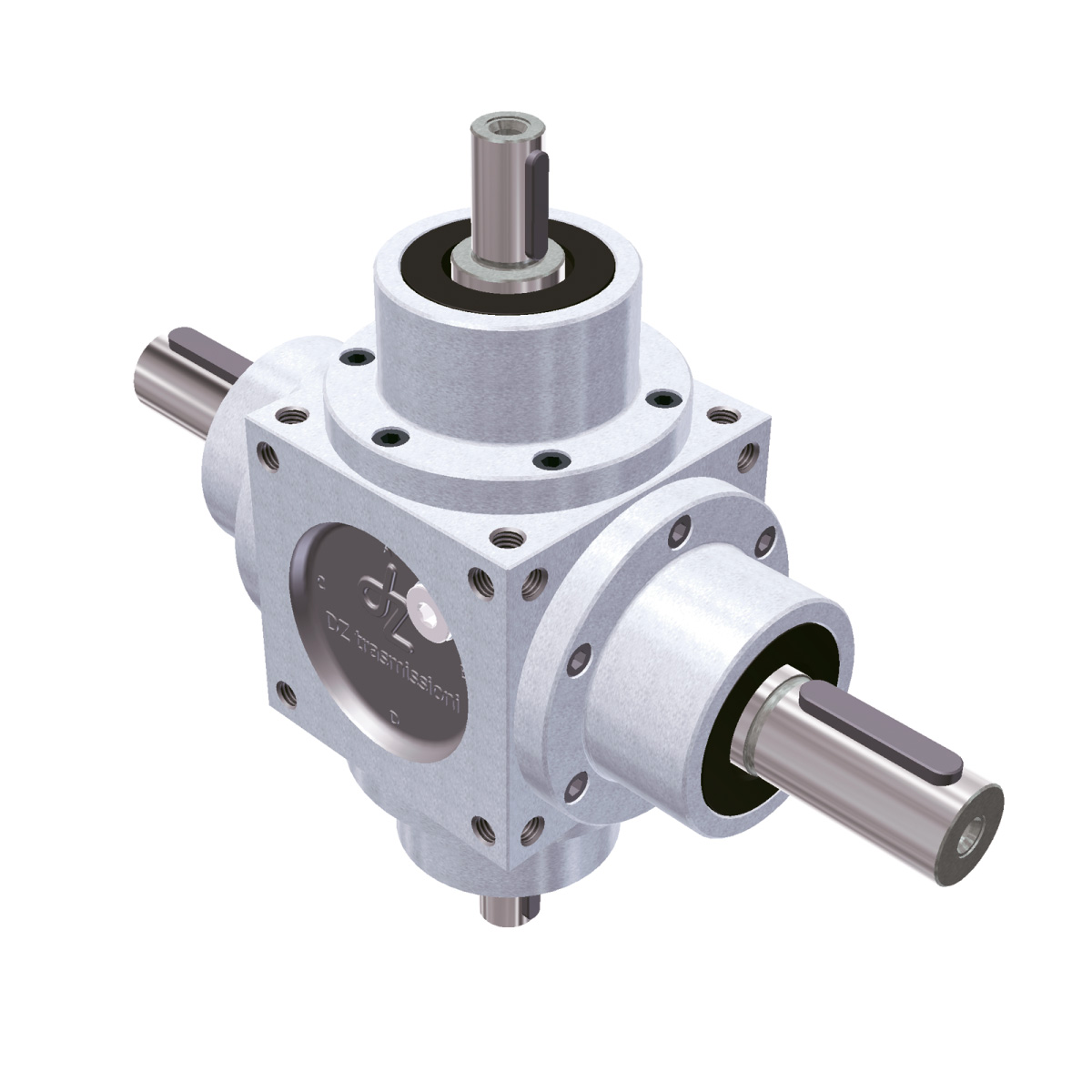

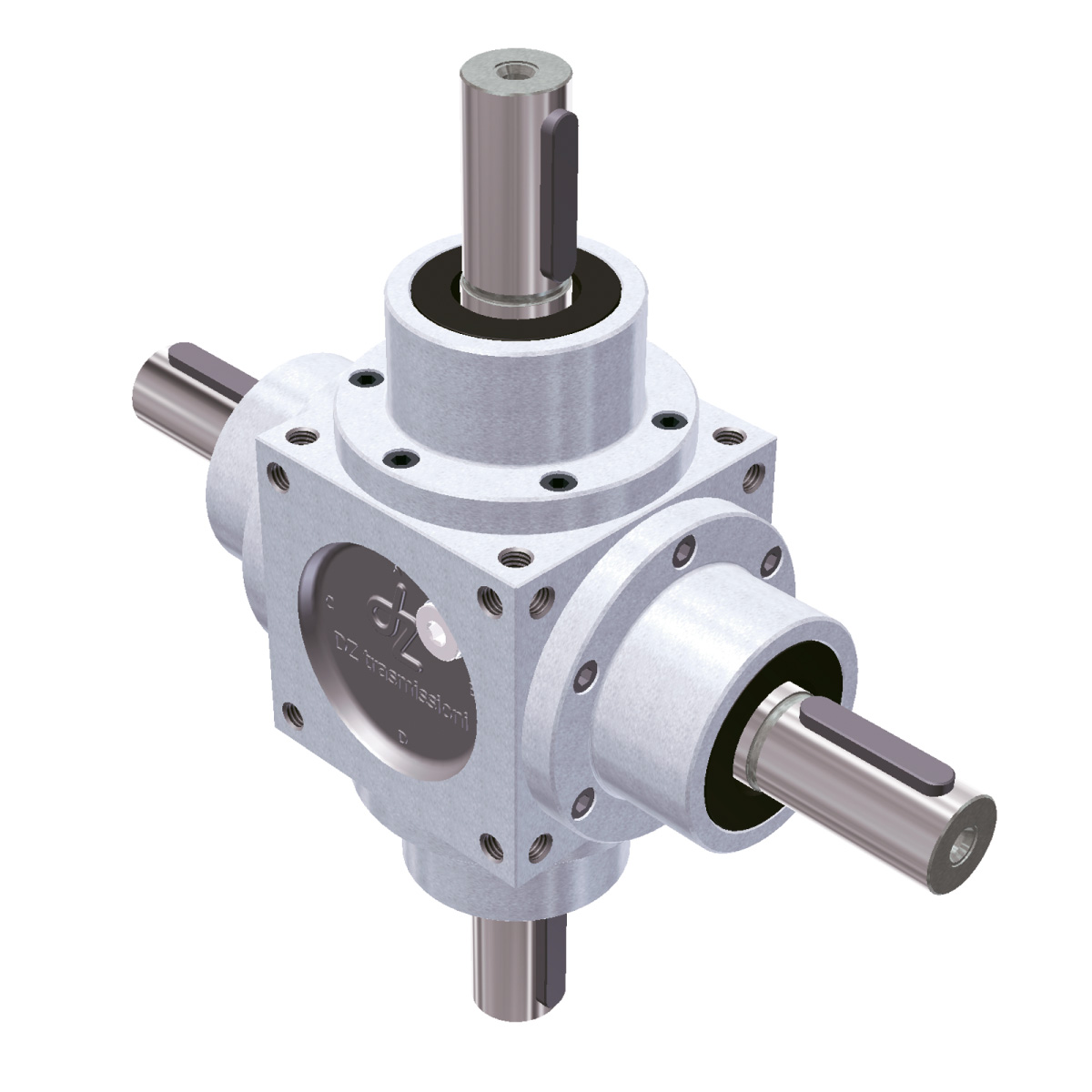

THE NEW QB INOX SERIES

Yet another innovative series, that arose out of thirty years’ experience in the production of bevelgears particularly suited to the pharmaceuticals and food sectors, and all contexts that present particular ambient or climatic conditions.

The QB INOX line offers the following high performance characteristics:

-

5 Sizes : 54 86 110 134 166

-

5 Ratios : 1:1 – 1:1.5 – 1:2 – 1:3 – 1:4

-

Input power: up to 112 kw

-

Output torque: up to 990 Nm

-

Output rpm: up to 3000 r/min

-

Overall bulk: maintains the same dimensions as the QB series

-

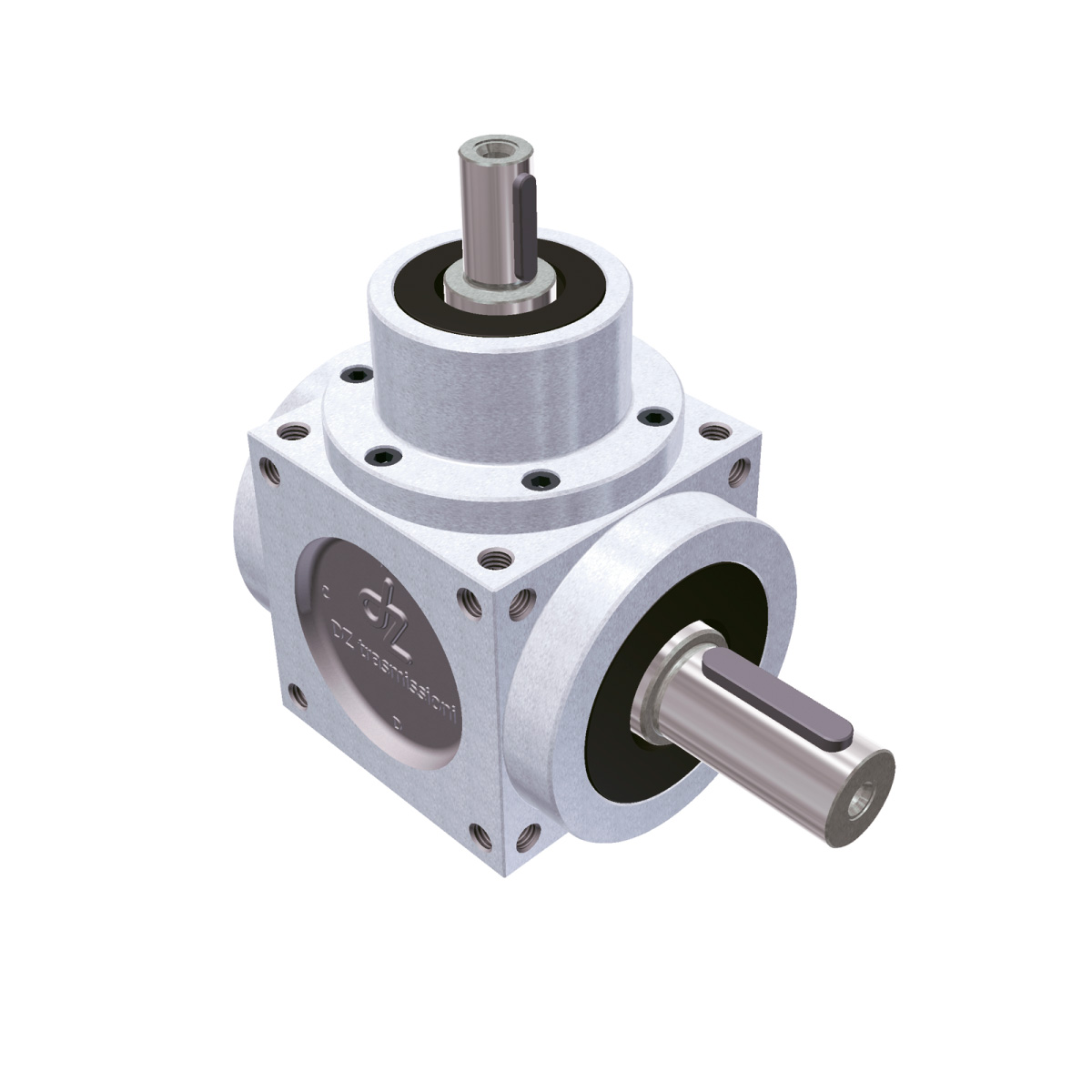

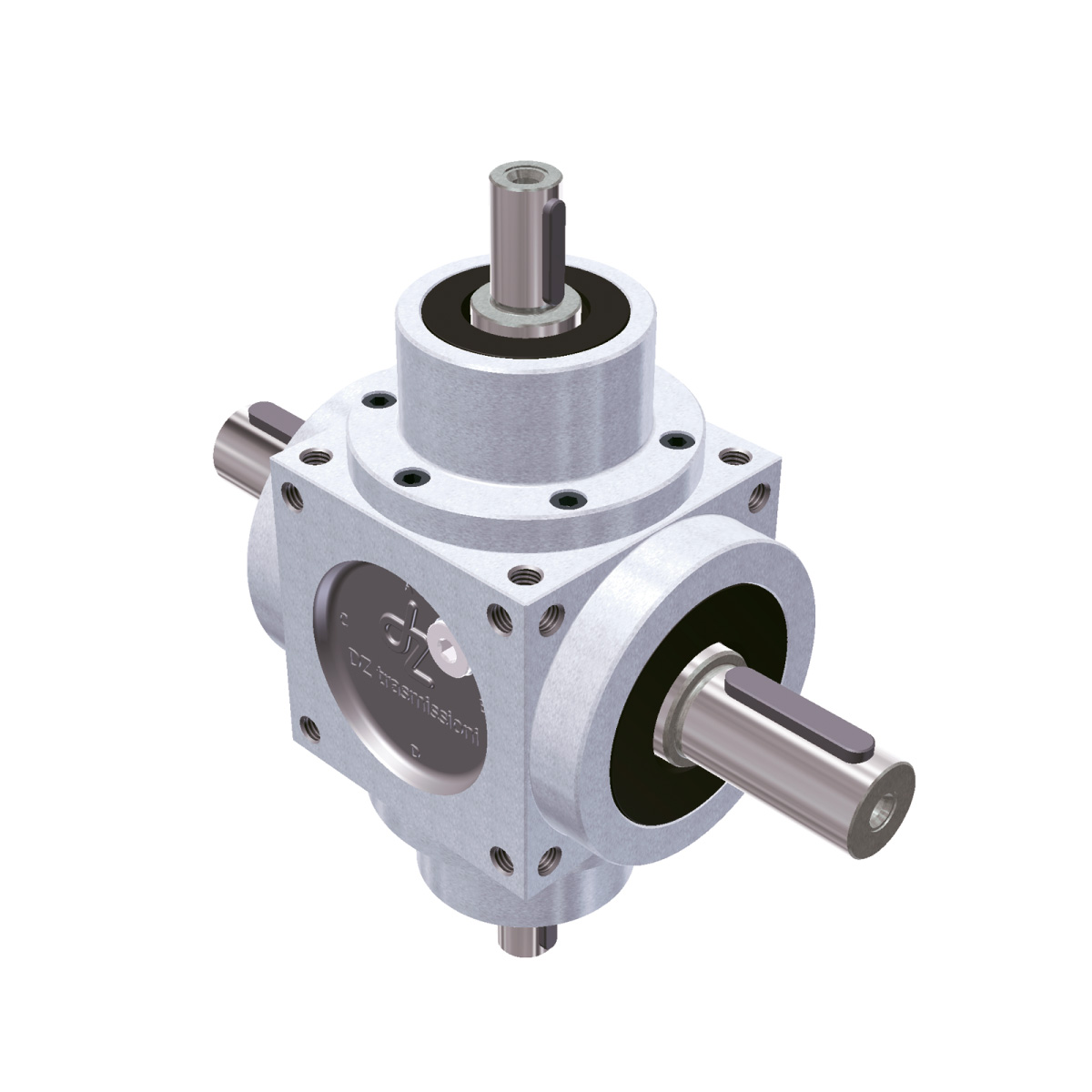

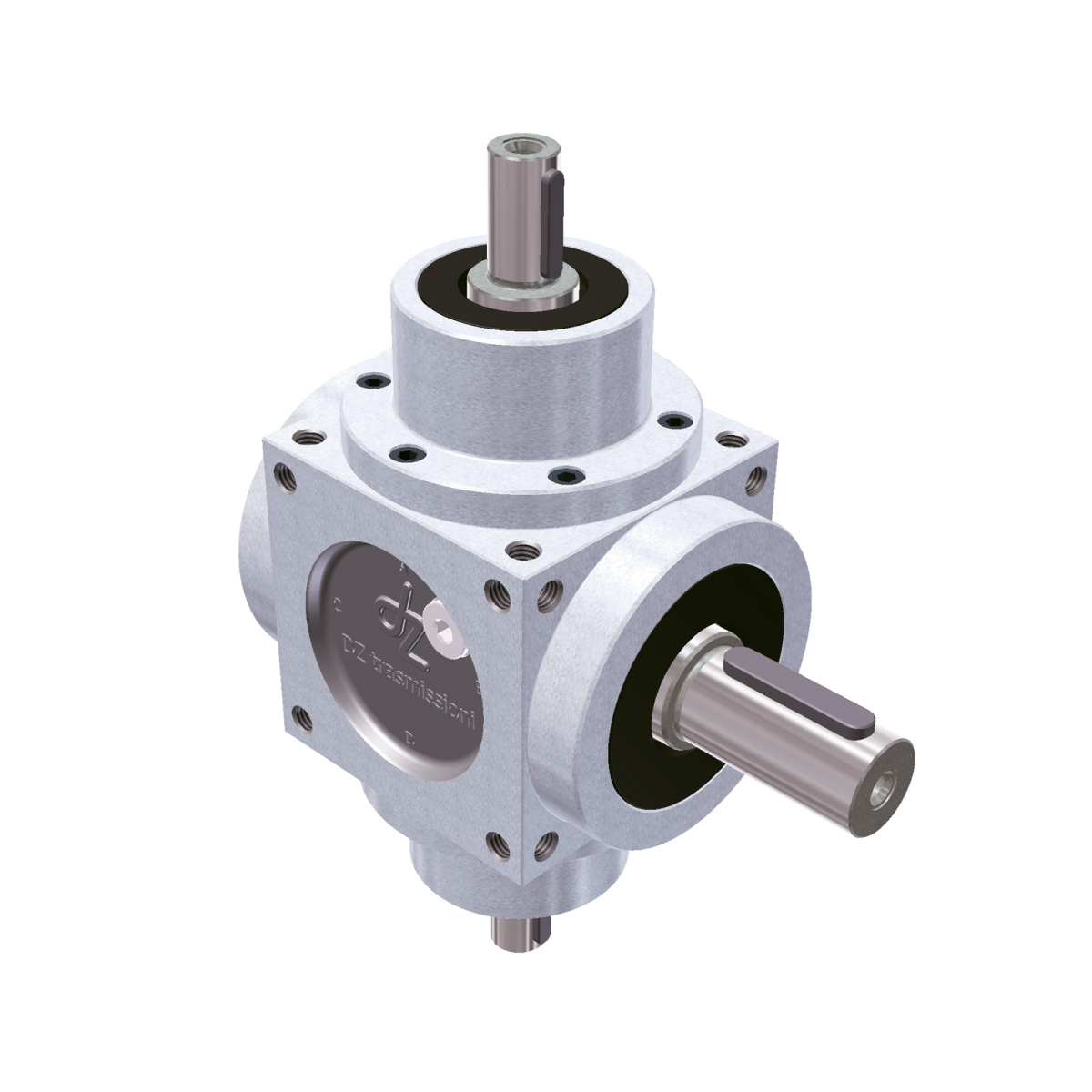

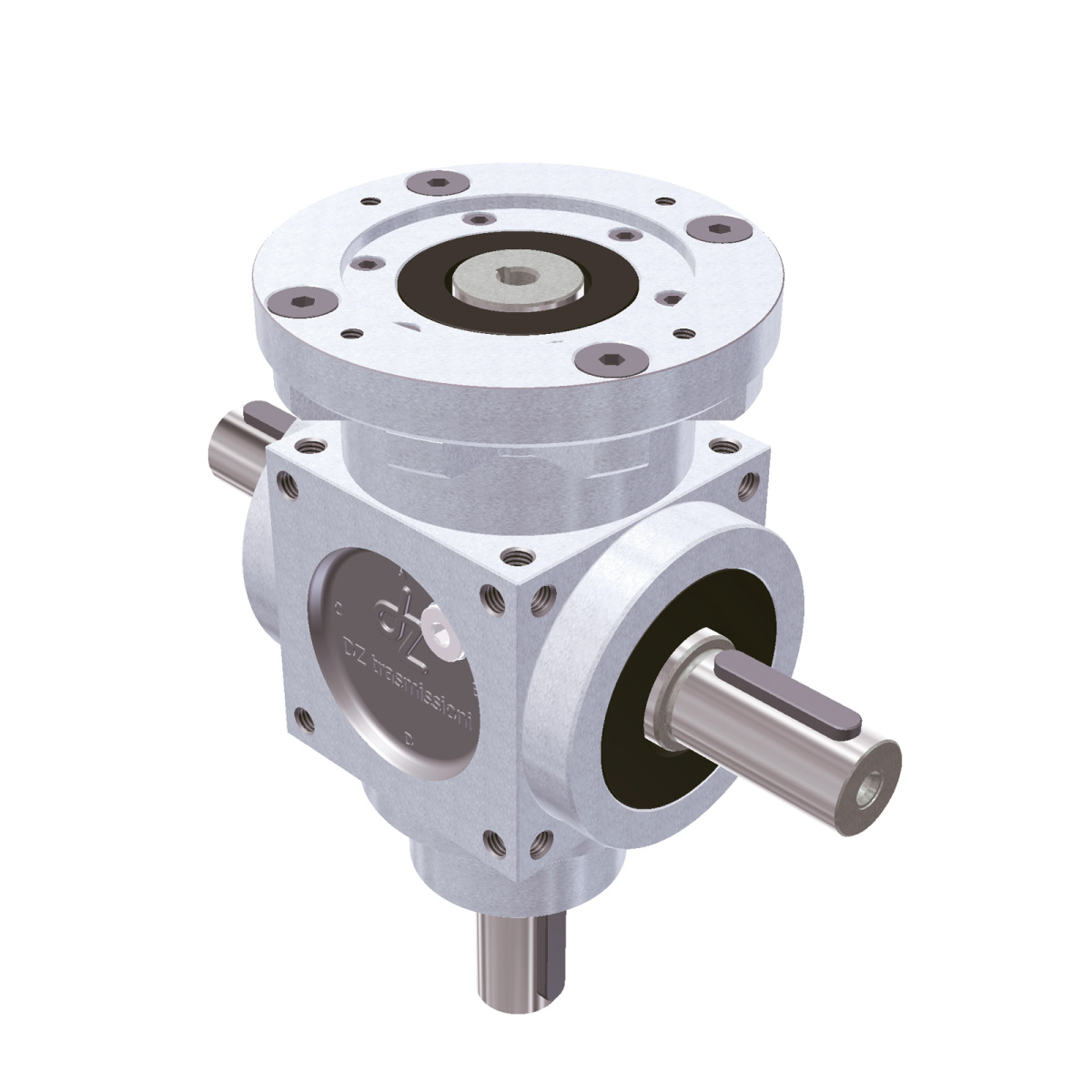

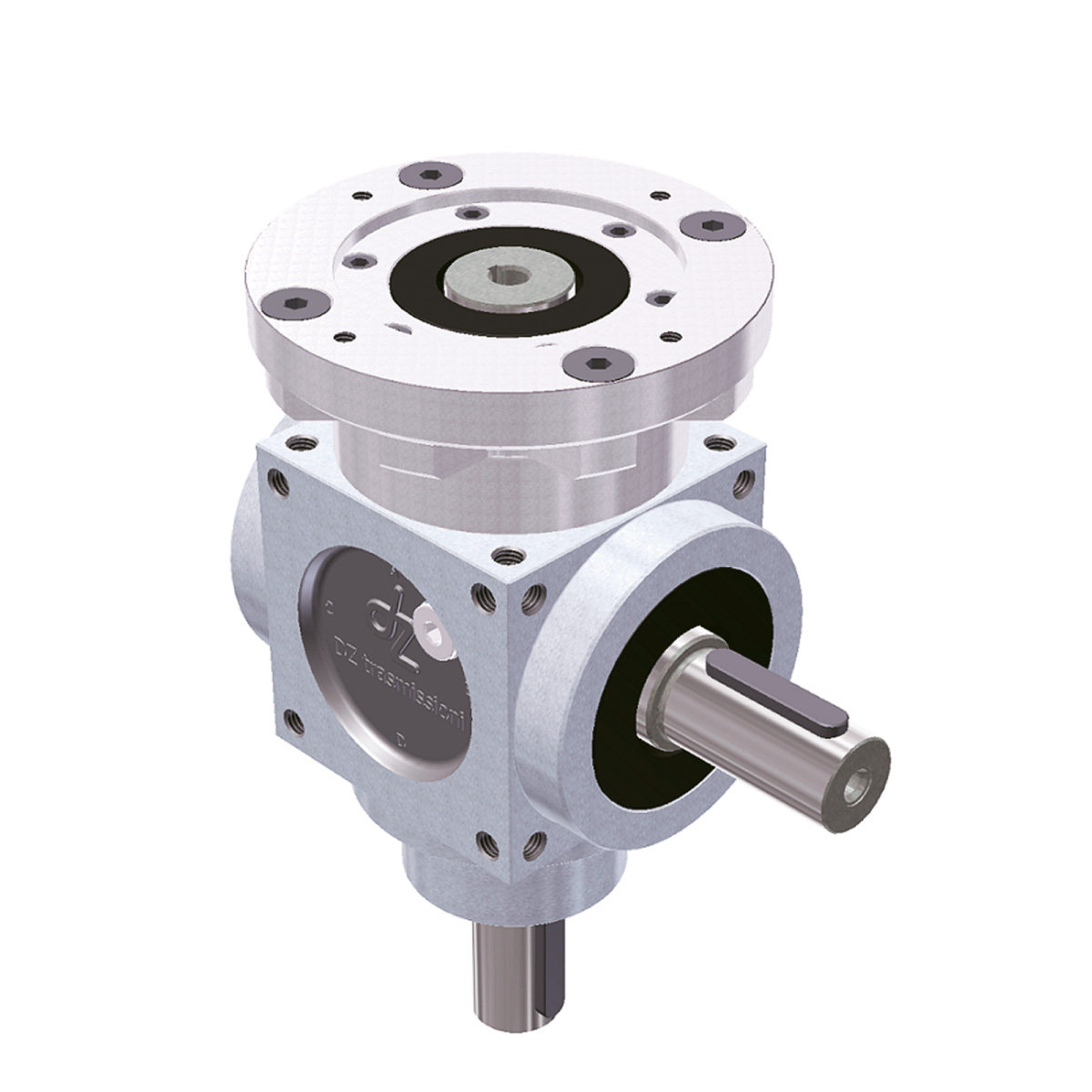

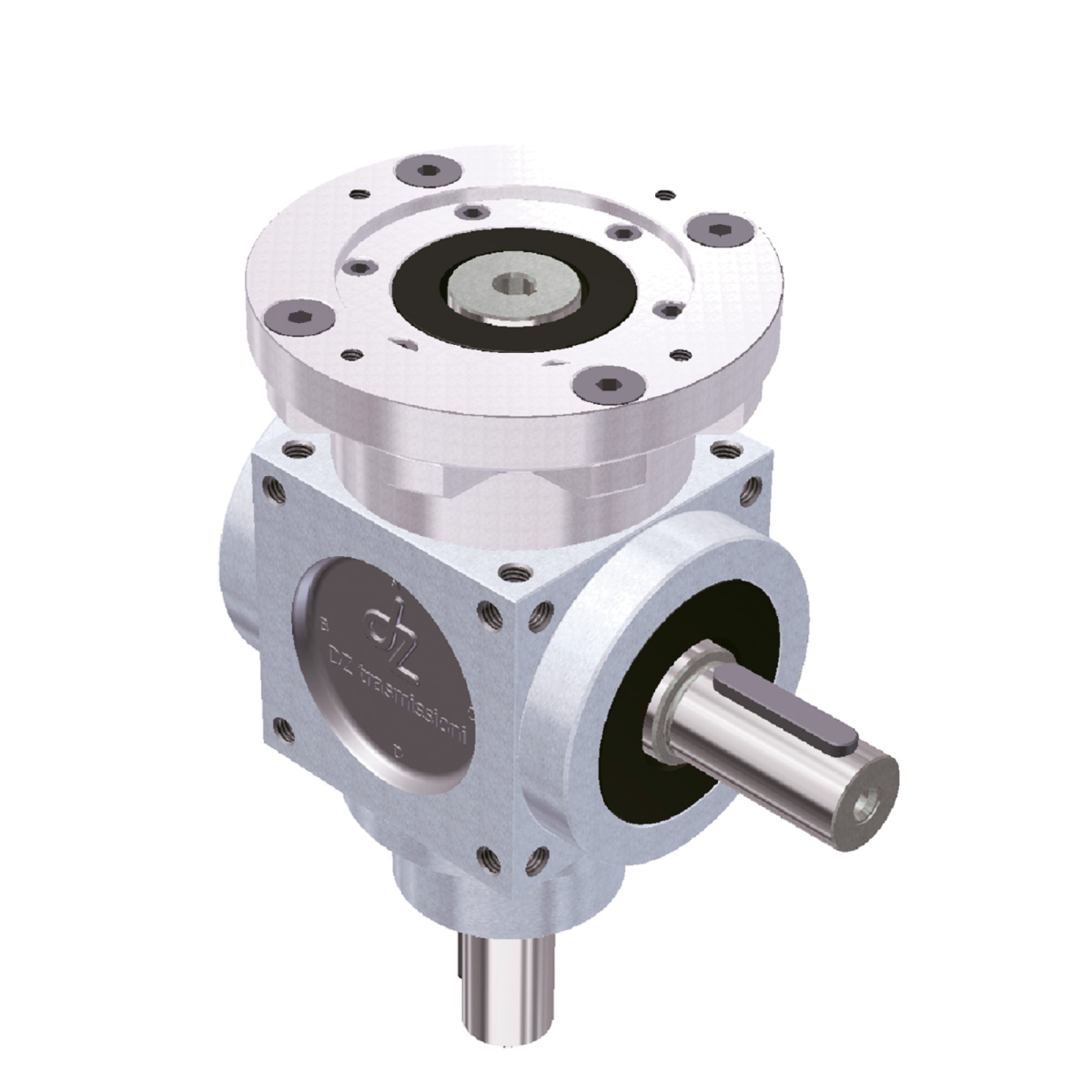

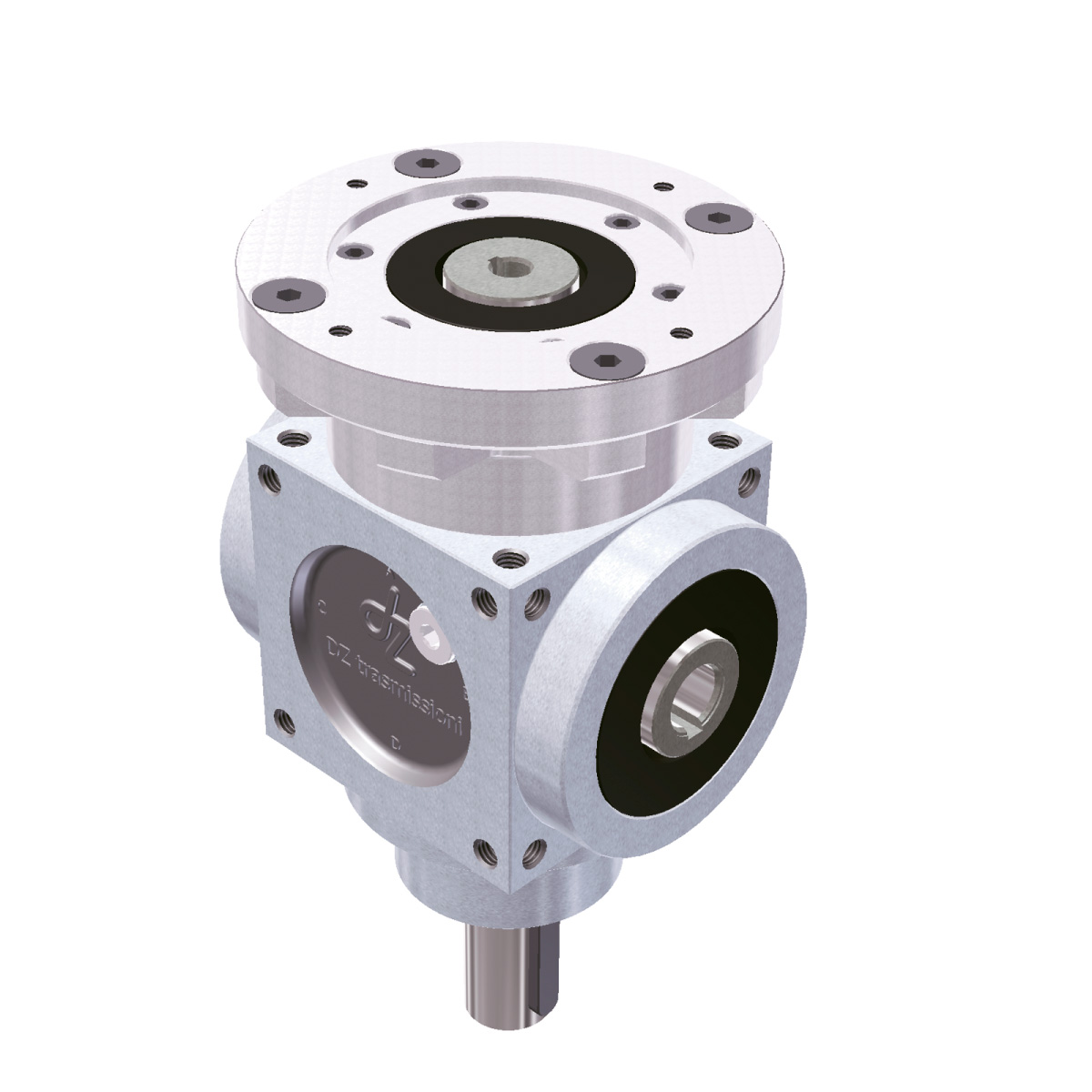

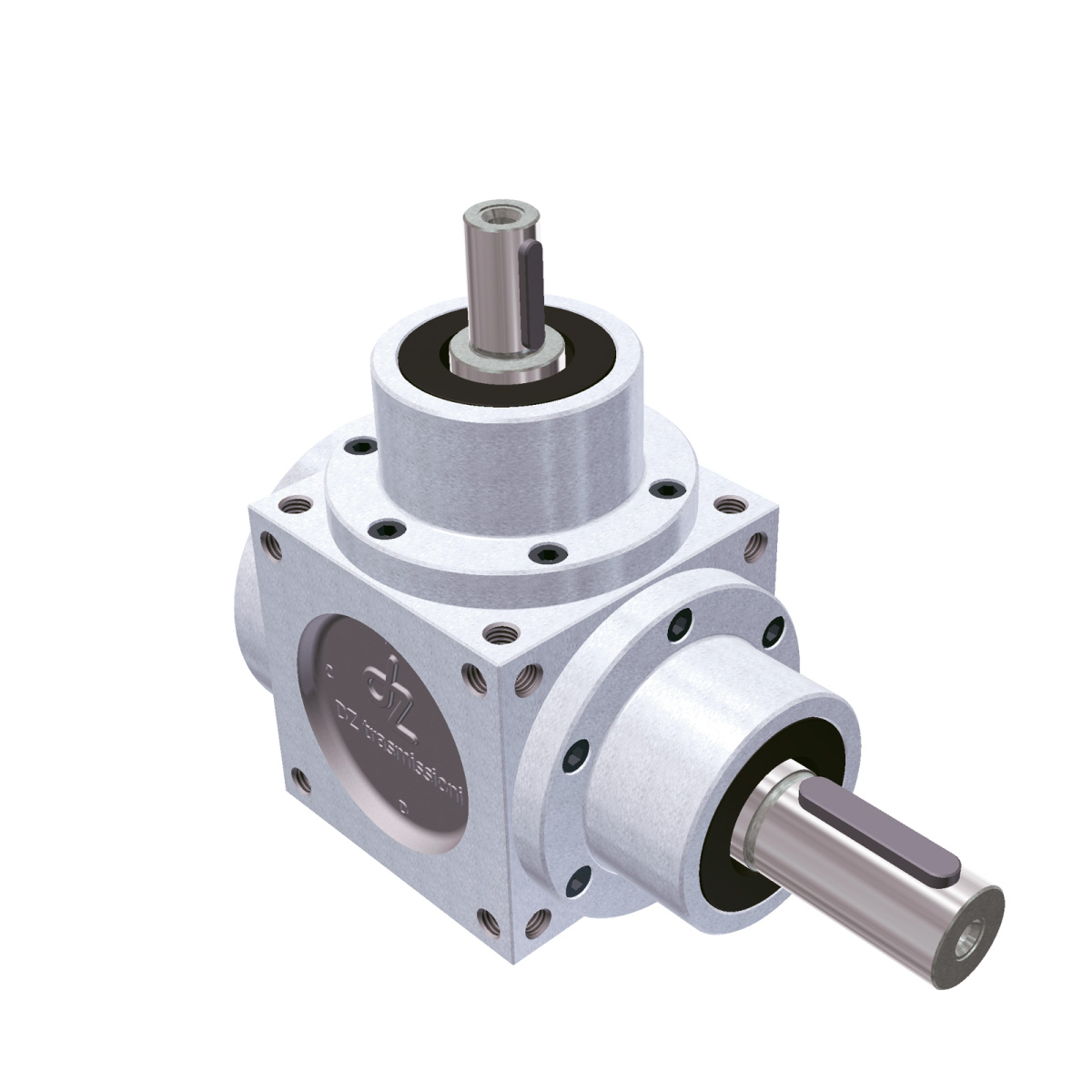

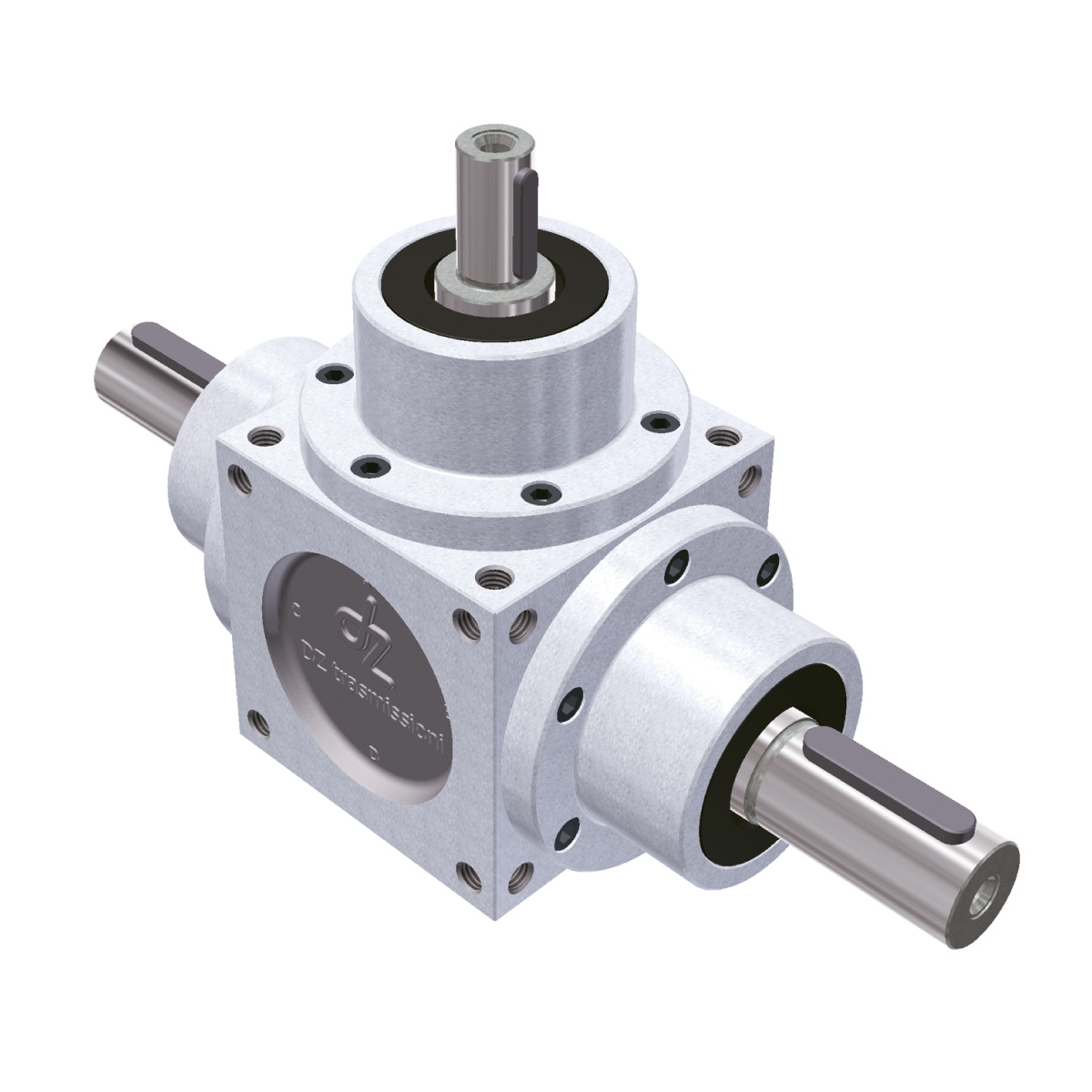

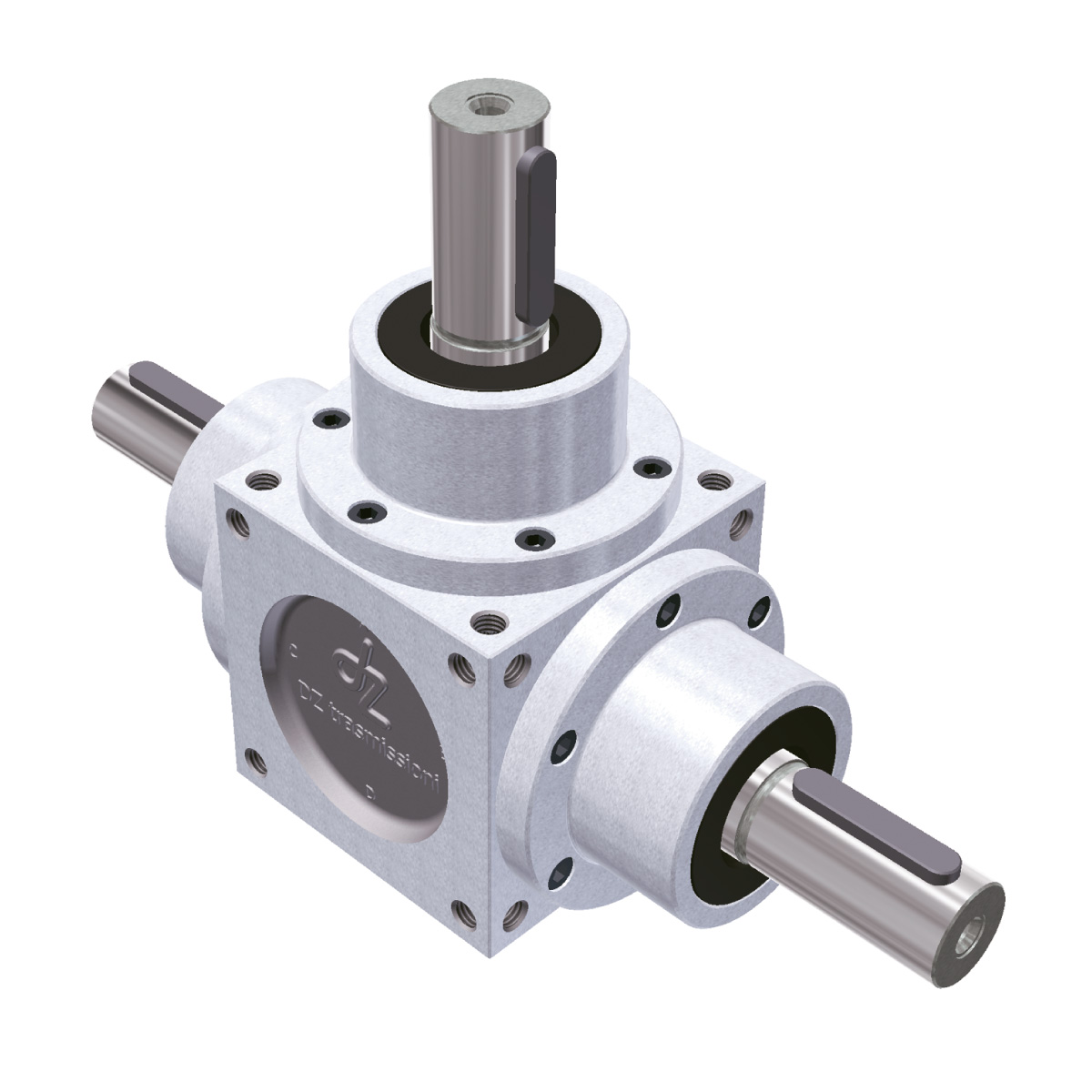

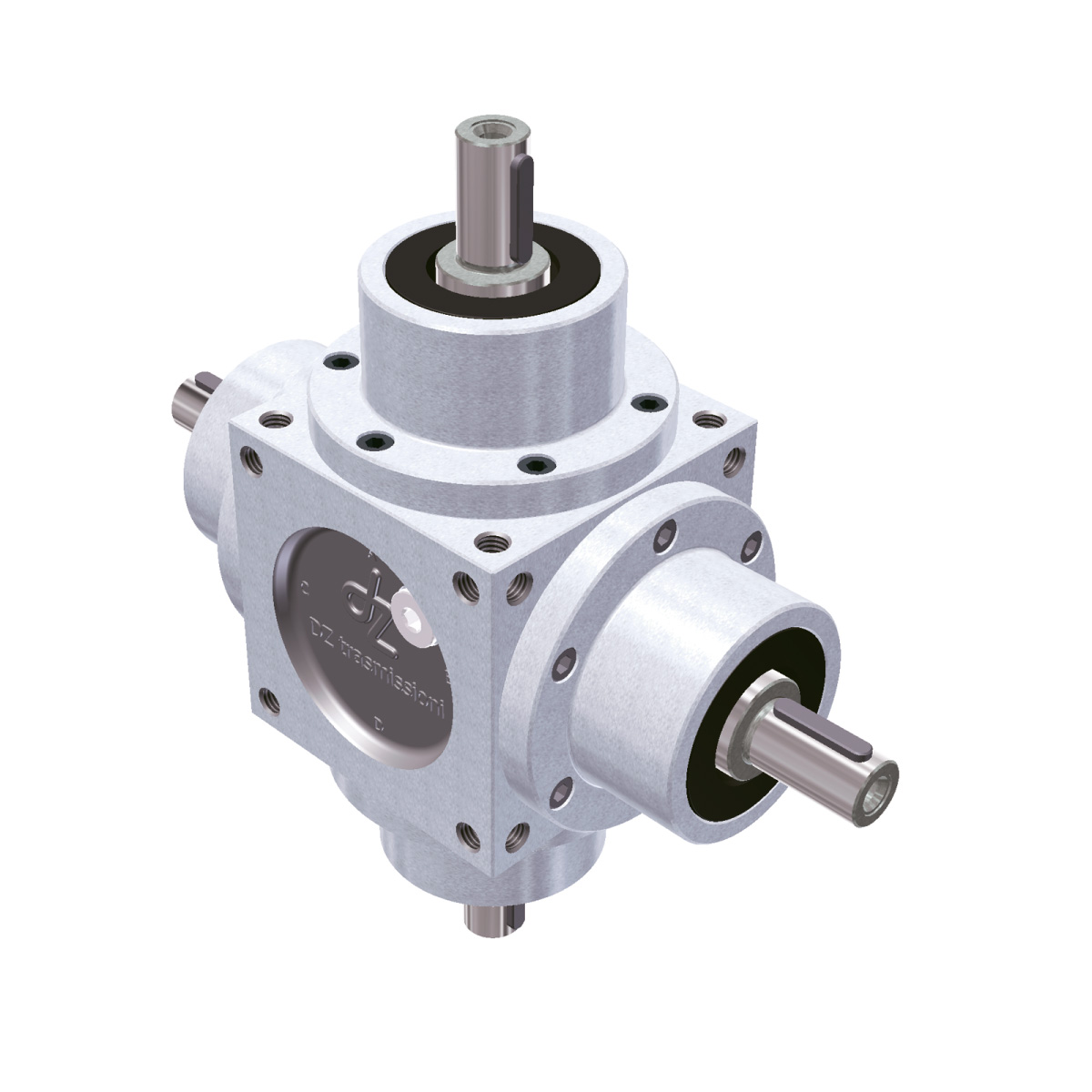

Design types: 1-2-3-4-5

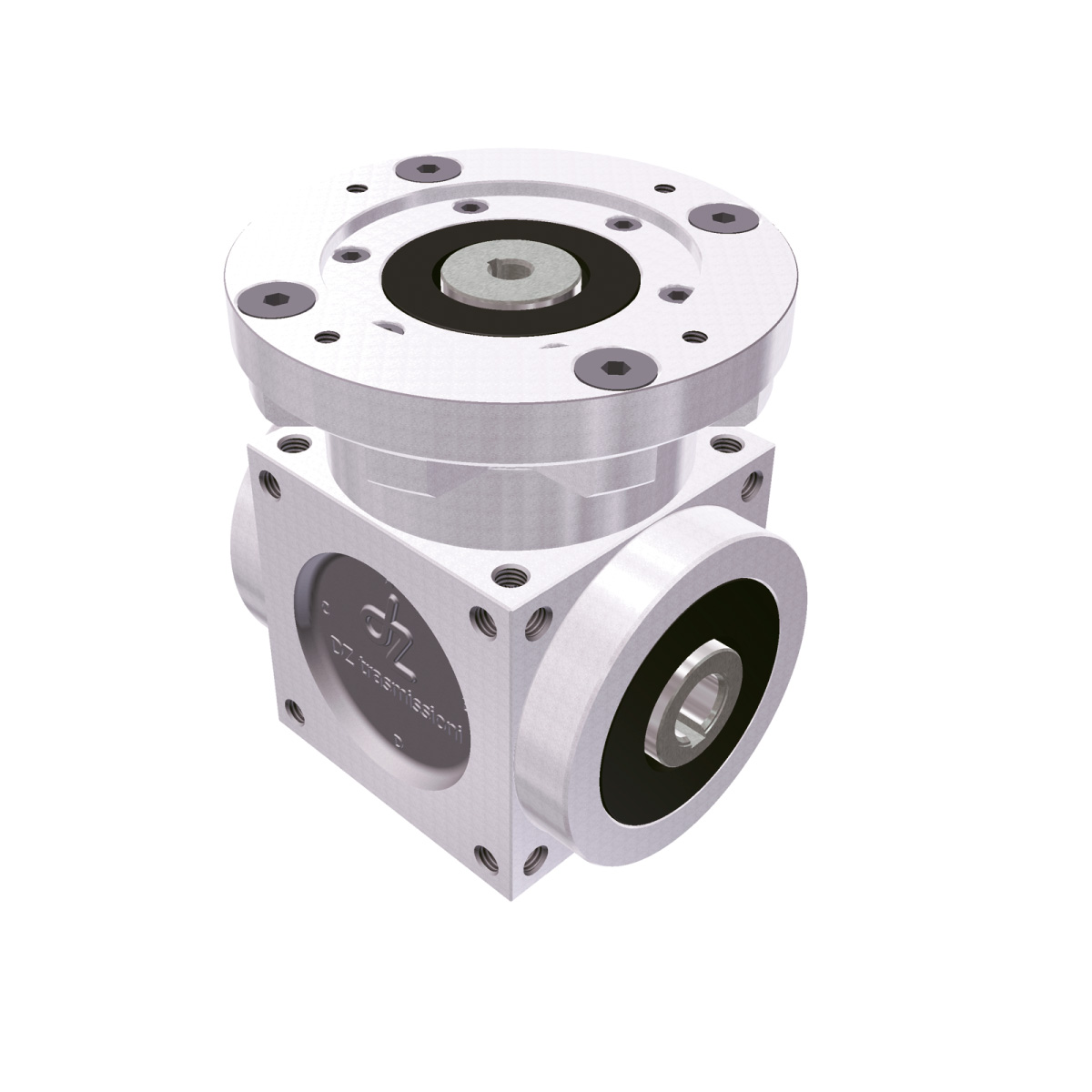

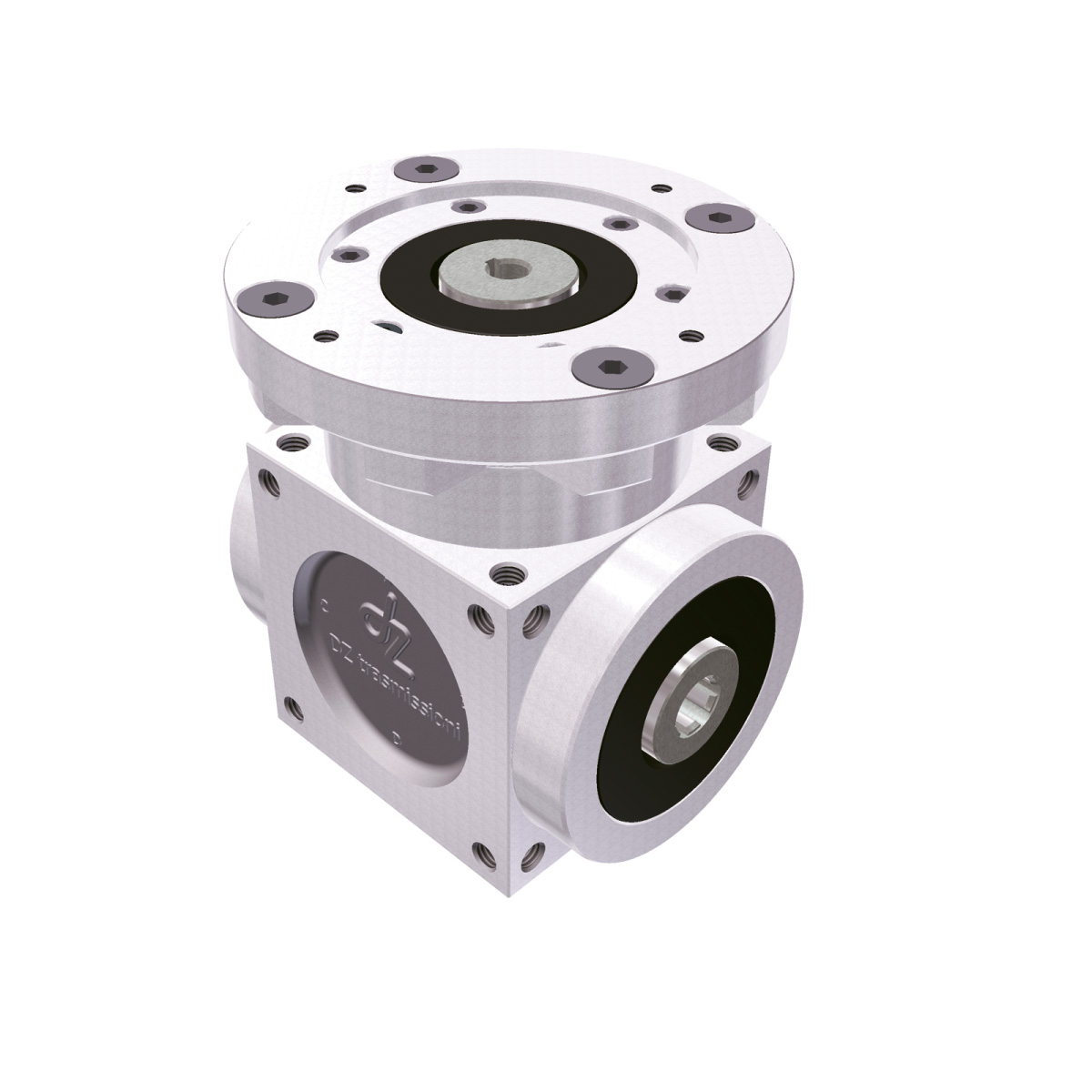

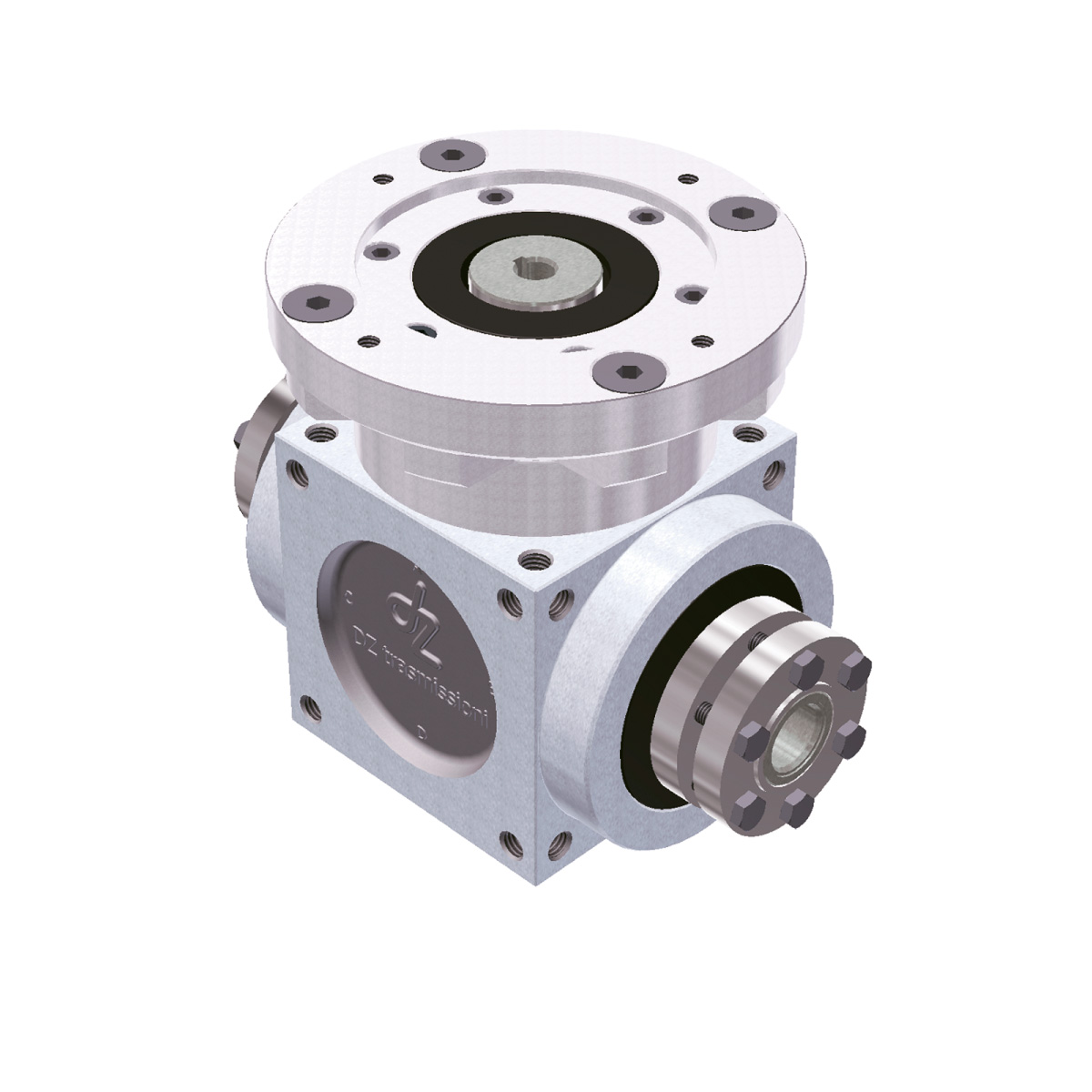

ELECTROPOLISHED CASING AND NECK FLANGES

Electropolishing is a chemical treatment that fully exploits the corrosion resistance characteristics of stainless steel. The aseptic nature of the surface offers easy maintenance, making it effectively a standard for the food, pharmaceuticals, and medical industries as well as being suitable for all situations requiring high resistance to atmospheric or processing agents. The electropolishing process uses special electrodes to remove a few microns of surface layer from the stainless steel, thus minimising the surface roughness.

The neck flange is fixed to the casing with cylindrical head hexagon socket screws UNI 5931/ DIN 912 in AISI 304 (A2) stainless steel.

The neck flange is fixed to the casing with cylindrical head hexagon socket screws UNI 5931/ DIN 912 in AISI 304 (A2) stainless steel.

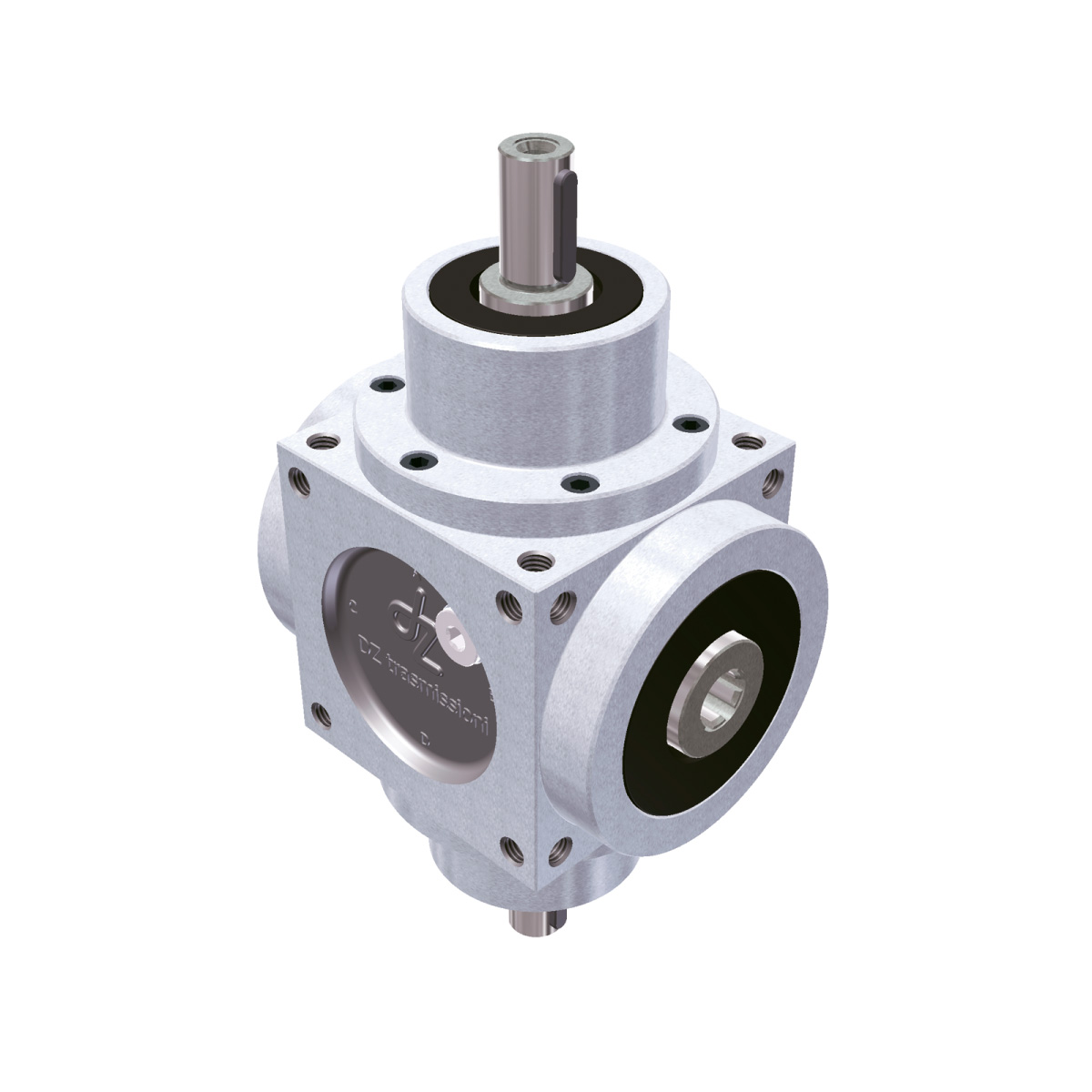

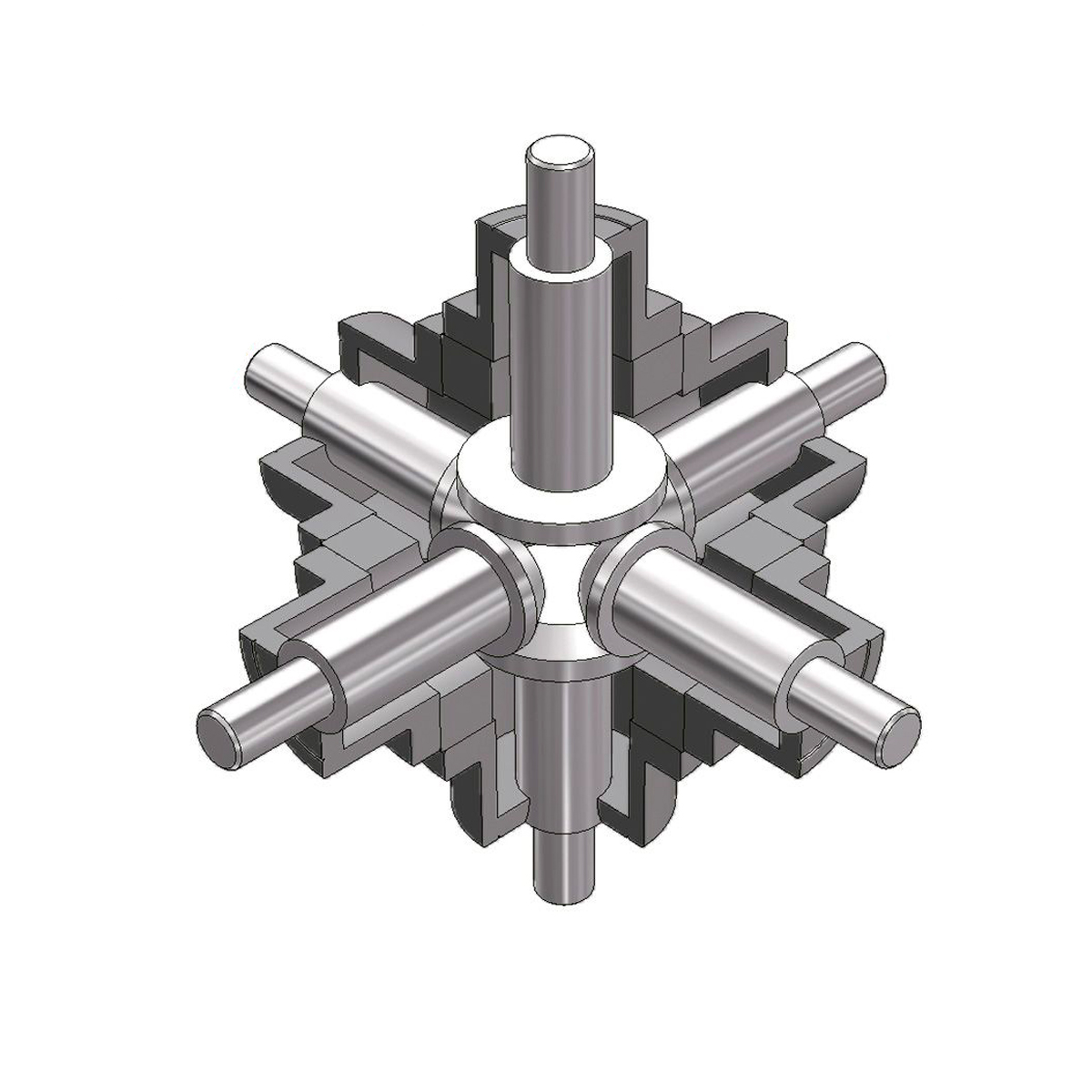

VARIABLE HOLE DRILLING

In order to provide a highly flexible product, the QB INOX series has fixing holes drilled on all 6 sides of the casing.

However, for particular applications, like the food sector, unused holes can compromise the effective sanitisation of the system. For this reason, we keep a warehouse stock of casings without holes, with drilling to be agreed in each case by filling in a simple form

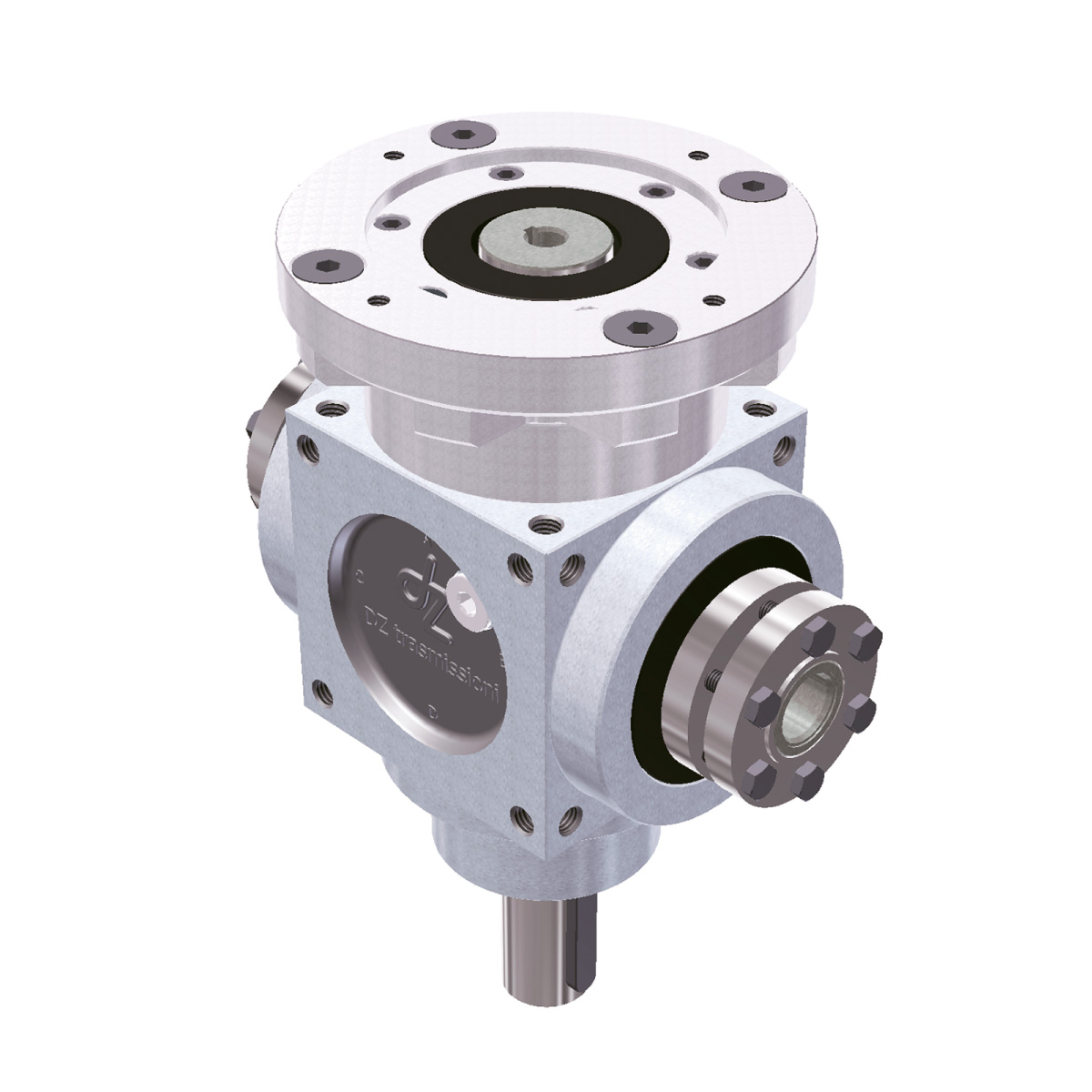

INPUT SHAFTS

The input shafts are made in AISI 316 stainless steel ground to h7 with UNI 6604-A coupling splines in AISI 304 (A2) stainless steel. Versions with PAM flange are available on request.

OUTPUT SHAFTS

The QB INOX series offers three types of output shaft, all in AISI 316 stainless steel, to satisfy any fitting requirements:

- Male shafts ground to h7, UNI 6604-A coupling splines h9

- Hollow shafts ground to H7, spline grooves H9

- Hollow splined shafts UNI 8953 NT

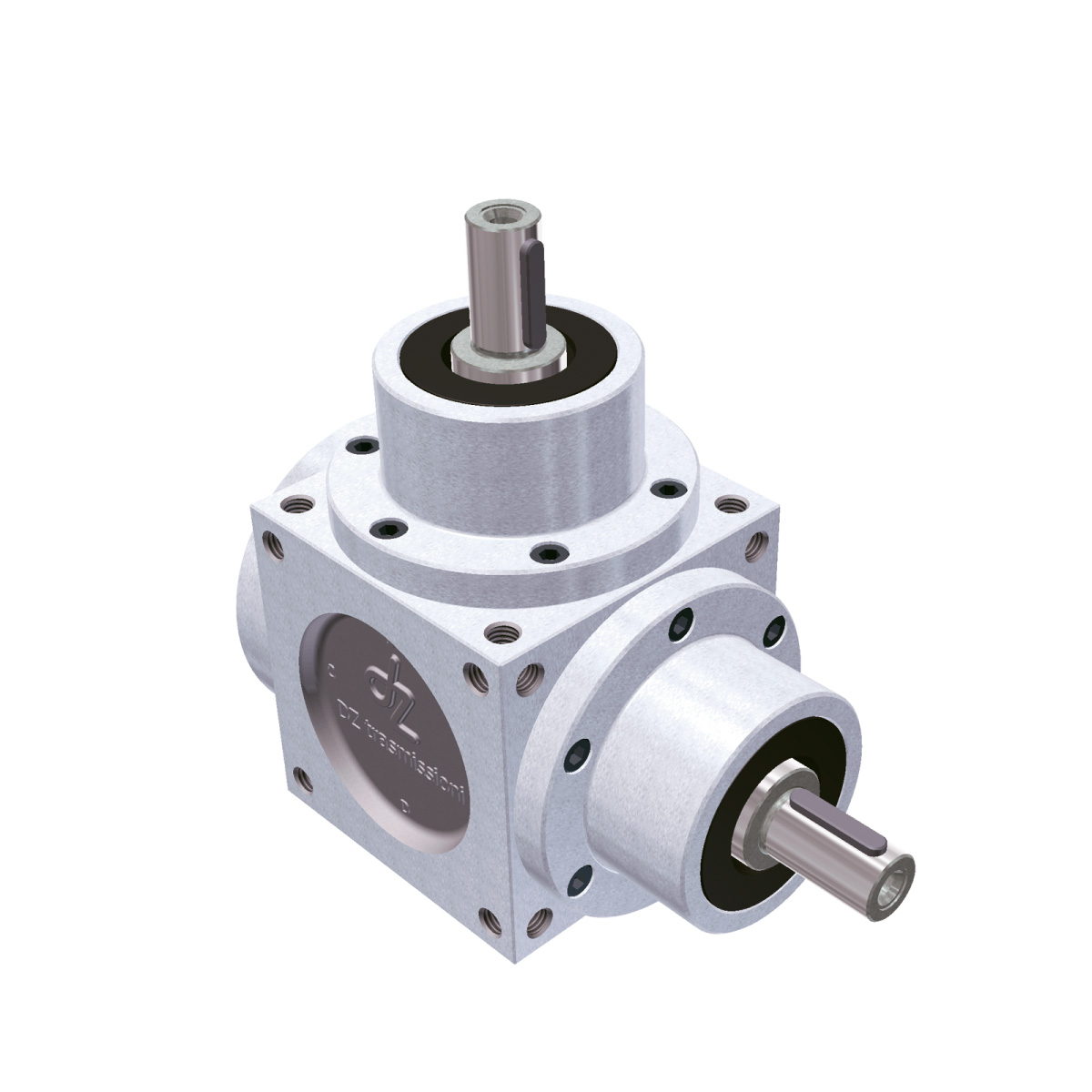

OIL FILLER CAP

In order to provide a product with as smooth a surface as possible, the QB-INOX series bevelgears have the oil filler closed with a NBR cap.

GASKETS

The gaskets on the QB-INOX series are flat lip DIN 3760 Type A in NBR. We also have alternative materials like Viton and silicone, and we collaborate with major companies in the sector who can provide a range of materials with specific certifications for food processing contexts.

(e.g. MOCA – CE 1935/2004)

(e.g. MOCA – CE 1935/2004)